Circuite de grad militar

- Toate proiectele militare și aerospațiale necesită mai multe funcționalități ale produsului comparativ cu generațiile anterioare.

- Există presiune asupra fabricării plăcilor de circuite de nivel militar și a le face suficient de robuste pentru a se conforma funcționalității în creștere.

- Fabricarea PCB-urilor, procurarea și asamblarea componentelor, all-in-one de pe o singură platformă simplă.

- Instalarea și reprelucrarea BGA și Micro-BGA cu inspecție 100% cu raze X, inspecție optică automată, curățare apoasă și servicii de testare PCB.

- În cazul în care PCB-ul nostru nu este utilizabil din vina noastră, puteți solicita despăgubiri, vă putem rambursa sau relucra pentru dvs.

Plăci de circuit de grad militar

Capabilități

-

Placer Speed:6000 de jetoane / ore

-

Timp de livrare:peste 25 de zile (de decis)

-

SMT:SMT, ansamblul orificiului traversant SMT cu o singură / dublă parte, ansamblul mixt cu o singură / dublă parte.

-

Dimensiune PCB:50 mm × 50 mm ~ 450 mm × 406 mm

-

Grosime PCB:0,5 mm ~ 4,5 mm

-

Min. Diametrul / spațiul BGA :0,2 mm / 0,35 mm

-

Calificări:ISO 9001: 2008

-

Precizie:<± 40 µm, în condiția de 3σ , CPK≥1

-

Min.Line / Track Width:3mil

-

Lățimea minimă / spațiul QFP0,15 mm / 0,3 mm, diametru minim / spațiu BGA: 0,2 mm / 0,35 mm

-

Test de fiabilitate :Testul sondei de zbor / Testul dispozitivului, Testul impedanței, Testul de sudare, Testul șocului termic, Testul rezistenței găurilor și Analiza secțiunii micro-metalografice etc.

Military Grade Circuit Boards

process

-

1Trimiteți fișiere către noi (Gerber și BOM)

-

2Citat în 24 de ore

-

3Confirmați fișierul și comanda

-

4Achiziționarea pieselor pentru fabricarea PCB

-

5Lipire, testarea controlului calității

-

6Ambalare și livrare

costul Plăcile de circuite de grad militar

Prototip + Achiziție componente + lipire + testare

Mai multe reduceri pentru prețurile de volum mediu

Acceptați T / T, numerar, card de credit, PayPal, transfer bancar etc.

Cele două fabrici ale noastre au suport pentru prețuri pentru comenzi diferite

Plăci de circuit de grad militar

Timp de plumb

Timpul mediu de producție pentru Asamblarea plăcii de circuite imprimate ) este prezentat pe tablă după ce toate piesele și componentele sunt lipite și instalate corect. Un comenzi PCBA :

- * Vă rugăm să verificați triplu toate fișierele și informațiile înainte de a plasa comanda.

- * Timpul de expediere depinde de țara de destinație și de metoda de expediere selectată.

Cum se comandă

Pentru a vă cita, avem nevoie de:

Gerber File

.brd / .pcb / .pcbdoc / .gbr / .cam

BOM

The Microsoft Excel format (.xls / .xlsx / .csv / or tab-delimited)

de ce noi

Ansamblu PCB Quickturn

- Fabricarea PCB-urilor și achiziționarea pieselor se efectuează simultan, economisind timp

- Comenzi prototip plasate în 24 de ore

- Cotați și comandați Online în orice moment

Preț competitiv

- Prețul nostru este unul dintre cele mai competitive din lume

- Proprie fabrică cu control rezonabil al costurilor, fără costuri ascunse în ea

- Acceptați T / T, numerar, card de credit, PayPal, transfer bancar etc.

- Cele două fabrici ale noastre au suport pentru prețuri pentru comenzi diferite.

Livrare la timp

- Metodele standard sunt DHL și FedEx, servicii door-to-door. Timp mediu de expediere doar 2-4 zile.

- Colaborați cu două companii de transport timp de mulți ani cu prețuri reduse

- Anti-static + Umiditate + Anti-vibrații Ambalare ; Certificat de inspecție

- Agent profesional În Iran, Pakistan

Asigurarea calității

- Toate produsele respectă IPC sau Standardele UL și standardele ROHS și REACH.

- 98% evaluare pozitivă și satisfacție a clienților Managementul și procesele standardizate din fabrică Servicii de testare multiple

Returnare și rambursare

- În cazul în care PCB-ul nostru nu poate fi utilizat din vina noastră, puteți cere despăgubiri.

- Vă putem rambursa contul direct sau re-prelucra plăcile inutilizabile sau re-fabricăm PCB-ul și vă putem retrimite la costul nostru, dar vă rugăm să cooperați pentru a rezolva problema dacă trebuie să refaceți.

PCB O SCARĂ DE FABRICĂ

Avem două fabrici de asamblare PCB, una în Shijiazhuang, una în Shenzhen.

Fabrica din Shijiazhuang este o divizie dedicată a serviciului nostru avansat (sectorul militar), echipată cu 4 linii SIEMENS SMT, iar fabrica Shenzhen este dedicată serviciului nostru standard (non-militar) echipat cu 4 linii YAMAHA SMT, radiografie și AOI, oferind un serviciu de asamblare de calitate la prețuri foarte rezonabile.

Putem furniza tot felul de interferențe electromagnetice (EMI) responsabile pentru multe cazuri de defecțiuni ale plăcii de circuite. EMI vă provoacă aproximativ 50% din ansamblul prototipului PCB, inclusiv ansamblul cablajului, injecția și acoperirea conformă.

Certificare

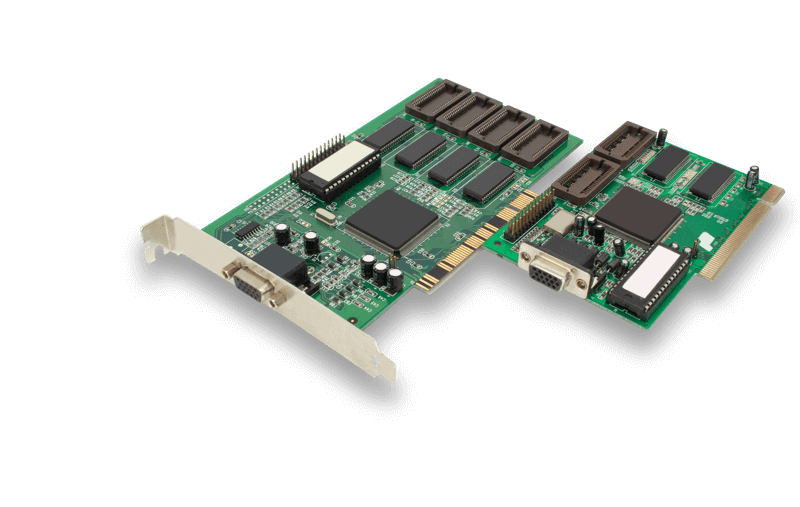

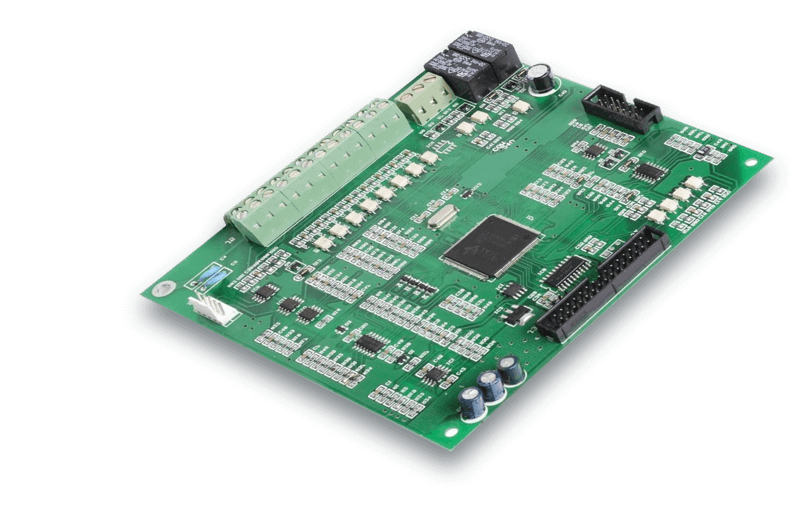

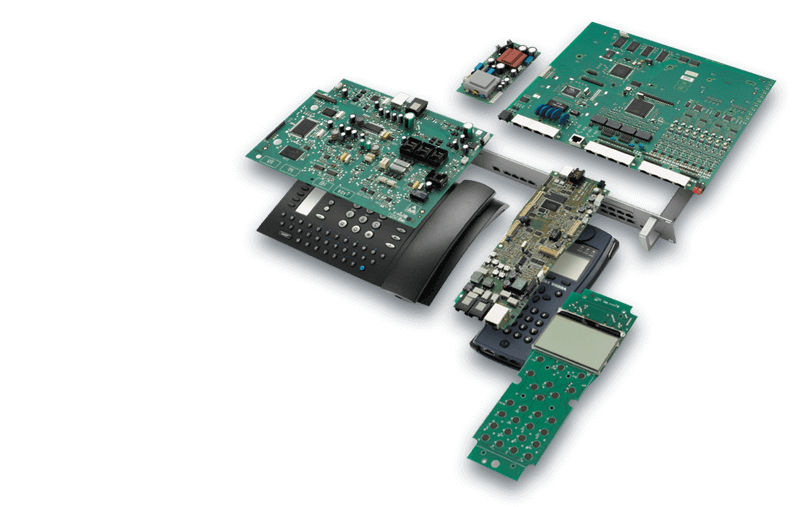

Arată produsele

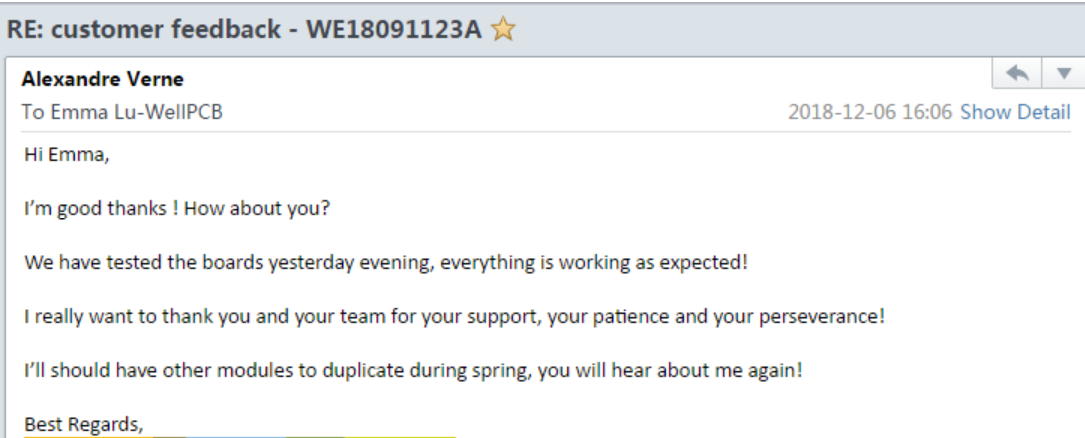

Mărturie

NXP France

12 sfaturi practice pentru proiectarea PCB-urilor pentru placile de circuite de grad militar

Toate proiectele militare și aerospațiale necesită mai multe funcționalități ale produsului comparativ cu generațiile anterioare. Cu acestea, există presiune asupra fabricării plăcilor de circuite de calitate militară și a le face suficient de robuste, astfel încât să se conformeze funcționalității în creștere.

Acest lucru necesită sau necesită în schimb implementarea unor tehnici specifice de proiectare și aspect. Unele dintre ele includ proiectarea unor astfel de plăci sub o pernă suplimentară de curent, folosind materialele corecte ale specificațiilor mil.

Să ne uităm la 12 sfaturi de proiectare pe care trebuie să le acordați atenție atunci când proiectați plăci cu circuite militare.

Table of Contents

All military and aerospace designs require more product functionality compared to previous generations. With such, there is pressure on manufacturing military-grade circuit boards and making them robust enough so that they comply with increasing functionality.

That demands or instead calls for the implementation of specific design and layout techniques. Some of them include designing such boards under an extra cushion of current, using the correct mil-spec materials, and keeping in mind stack up considerations, among others.

Let us look at 12 design tips that you need to pay attention to when designing military-grade circuit boards.

Military-Grade Circuit Boards Design Rules

Equipment that contains military-grade PCBs has to function faultlessly under harsh conditions. For this reason, their manufacturing process is identifiable by minimum tolerance and high precision. Several design rules must be adhered to when designing military-grade circuit boards. The layout, design, fabrication, and material selection need to follow stringent standards. Failure to follow such rules would bring about a malfunctioning board that would then affect the whole equipment’s functionality. Before you design a circuit board, you must have a plan in addition to doing and not doing it.

Military-Grade Circuit Electronic Components Performance

Unlike other types of PCBs, military-grade printed circuit boards are supposed to withstand thermal loads and maximum current to ensure reliability. Their design process must meet several standards aimed at ensuring their performance or functionality.

Some of the performance requirements that military-grade circuits have to meet are; FCC EMC standards, ISO 9001, and AS9100 standards, among others. The manufacture of safe, high-performing and reliable military-grade PCBs must follow some rules, an aspect that ensures useful functionality of military equipment even when under extreme conditions.

circuit board. Computer motherboard. 3d illustration”/>

circuit board. Computer motherboard. 3d illustration”/>Military-Grade Parameters for Designing the Perfect PCB

Printed circuit boards meant for military equipment require detailed design compared to those involved for other applications such as the medical field or computers. For this reason, there are specific parameters intended for designing the perfect military-grade PCB.

Some of the most basic and essential design parameters aimed at developing the ideal PCB include factoring in crucial issues such as thickness, lamination, and the number of layers that a military-grade board must-have.

Another worthy parameter worthy of attention, especially when it comes to military-grade PCB is flammability. Military-grade PCBs should be somewhat resistant to burning and high temperatures.

Separation of Low-Frequency and High-Frequency Components

As mentioned earlier, designing military-grade PCBs is not an easy undertaking, as you may imagine. It requires precision and a lot of time to manufacture. For instance, power must not be kept together with ground planes when it comes to such designs.

Additionally, low-frequency components have to be apart or separate from high-frequency components.

If they are not kept separate, they may degrade the signal and bring about some noise, an aspect that is highly unacceptable in military-grade PCBs. When designing military-grade PCBs, manufacturers have to ensure that they separate low-frequency from high-frequency components.

Verify the Impedance Calculation

When it comes to printed circuit boards, the term ‘impedance’ is ubiquitous. Impedance is the sum of reactance and resistance of an electrical circuit measured in Ohms. The verification of impedance calculation is critical because it is somewhat challenging to test aerospace and military devices in a real environment.

There are several tools that one may use to verify impedance if need be. Impedance calculation will reveal as to whether there are some changes or alterations to the design that need attention.

PCB Trace Should Not Be More Than 45 Degrees

When designing military-grade circuits, designers need to ensure that the PCB trace routing is not higher than 45 degrees. It is also preferable to use curved traces. one of those essential design techniques that ensure that the transmission of current is smooth throughout the circuitry.

Trace angles that are of 90 degrees are forbidden based on the fact that the flow of current will hit the top of the 90- degree turn and go ahead to reflect backward. will then create a ripple effect that brings about an unclear signal.

Watch out for “Stacking” Issues During PCB Layout

When designing military-grade printed circuit boards, issues to do with stacking often come up. Designers need to watch out for stacking issues during PCB layout. Here, the rule of the thumb is to ensure the avoidance of fragile cores.

Additionally, designers need to keep at the back of their mind the type of material they choose to use in the internal layers of the board. Ideally, designers of military-grade printed circuit boards need to do away with two to three mil cores used as internal stack-up.

DFT is Essential

DFT, or Design for Testing is necessary. All the manufacture of military-grade printed circuit boards has to be in a way that it becomes easy to test them outside the system independently.

When it comes to military-grade printed circuit boards, testing is essential to ensure that the final product will always function reliably for many years to follow. Design for testing is helpful in the initial layout plan. A lack of a robust test process may see a manufacturing firm rolling out defective printed circuit boards that will later fail in the field.

Thermal Management

Thermal management involves the careful selection of components and materials that can withstand some of the most extreme heat and temperature conditions. For instance, metal-core printed circuit boards find substantial use in aerospace and military applications that generate significant heat and power.

When designing military-grade printed circuit boards, it is essential to factor thermal management issues by choosing some of the best materials and components that can withstand extreme heat and temperature conditions.

There are different types of materials, such as aluminum and epoxy-based materials that one can use. But when it comes to military-grade circuits, manufacturers need to go materials that can withstand extreme heat.

Reasonable Handling of RF Issues

RF interference takes place the moment some unwanted radio frequency signals go on to disrupt the use of specific equipment. Electrical equipment and transmitters are some of the most common causes of interference. When it comes to designing military-grade printed circuit boards, manufacturers must have in place mechanisms for handling RF issues.

To effectively handle RF issues, it’s essential to ensure that cables are short and have heavy gauge shields. Additionally, it’s important to double-check the connectors to verify quality signal and also install RFI filters along the signal path.

DFM Test

Military standards also call for more rigorous testing before the final production process. Apart from other types of tests, DFM, also referred to as Design for Manufacturability, is a must when designing military-grade printed circuit boards.

Even though this type of testing is a bit extensive, it is highly recommendable based on the fact that it ultimately brings about a superior product. Design for Manufacturability (DFM) is a test that looks at the underlying performance of the circuit board as well as other aspects such as variable humidity, thermal duress, and high electrical amperage, among others.

The use of Perfect Annular Rings

An annular ring is a technical term designated for the area between the conductive edge of the copper pad and the hole drilled into a via. Having in place messed up annular rings on the printed circuit board may ultimately affect the functionality of the PCB. To achieve perfect annular rings, manufacturers of military-grade PCBs ensure that they drill the holes effectively at the center of the via pad.

In reality, though, the accuracy and precision of the drilling depend on the machine that a manufacturer uses. When it comes to military-grade printed circuit boards, manufacturers need to ensure that there are enough annular rings on the board. Additionally, designers –especially those tasked with producing military-grade PCBs- can play a huge role in setting the best size on the design. Annular rings are ideal for military-grade PCBs, and it’s essential to ensure manufacturers get the right size.

Summary

For more than a decade, WellPCB has been providing high-quality, heat-resistant, and long-lasting printed circuit boards for a variety of defense and military applications.

WellPCB is ISO:9001:2008, RoHS, and UL certified. It means that you can rely on our printed circuit boards that can perform well, even under challenging conditions that are ideal for military equipment.

If you have defense and military applications that require quality printed circuit boards, WellPCB might turn out to be a wise and a very cost-effective option for you.

Unlike plenty of other printed circuit board manufacturers out there, we also do the assembly.

Explore our flexible PCB production services to find the best options for your application. At your earliest convenience, feel free to reach us for a free and also accurate quote regarding your order.

Hommer

Hi, I am Hommer, the founder of WellPCB. So far we have more than 4,000 customers worldwide. Any questions you can feel free to contact me. Thanks in advance.